PUR (Polyurethane) Panels V/S Rockwool Panels

PUR as well as rockwool sandwich panels are 2 of the most usual sorts of protected sandwich panels around. This blog post will list the distinctions in between both panels.

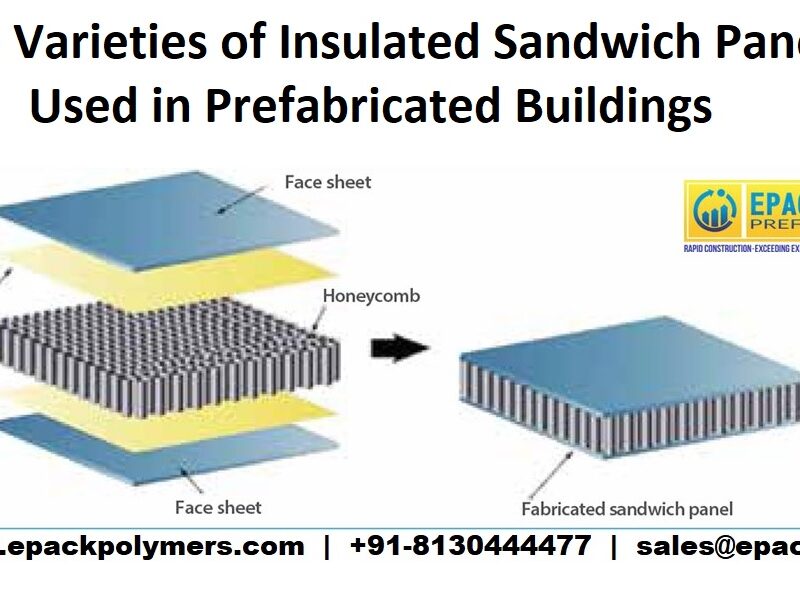

First of all, a tiny intro regarding sandwich panels. Sandwich panels have a core layer which is sandwiched between 2 metal sheets. Thus they obtain their name. The core layer forms a supports to both external layers, that results right into a composite structure with high stamina by light material weight. While Glasswool Panels are widely understood for its fire-resistive capabilities, polyurethane panels too have their very own benefits. The major distinction between the two panels remains in the insulating core product.

PUF Panels

The core protecting layer in PUF panels is polyurethane foam– PUR or PU. Throughout the manufacturing process, the product is poured in between two layers of GI sheets. The foam that is put strengthens with it is available in contact with the air. This strengthened layer glues the two sheets with each other, thus making a monolithic product with really high insulation buildings.

When it pertains to PUR, which means Rigid polyurethane, the insulation properties are extremely reliable also. These are light-weight panels which can be bound to several products. These paels have very high toughness to weight proportion. These panels are flexible and as a result discovers application in a wide range of items, because of its high insulation capacities.

Rockwool panels

The core insulating layer in rockwool panel is the rock wool itself, which is occasionally likewise referred to as mineral woollen. This mineral woollen or rockwool is glued in between the two GI sheets as well as develops a monolithic structure.

In rockwool panels, the core insulation layer is made of mineral wool. The rockwool layer holds both sheets of steels together. Mineral wool is just a coarse material which is crafted by rotating liquified mineral or rock products like slag as well as porcelains. Mineral wool is majorly used for audio proofing as well as fire-protection.

The key areas of distinction in between PUF and also Rockwol panels remain in its:

1. Insulation Features

2. Fire resistive capacities

3. Audio isolation

Let’s take a look at these buildings in some minor detail as adheres to:

Insulation Features

Polyurethane has higher insulation worth than that of rockwool. As an example, a 50 mm thick PUR or PUF panel provides the very same quantity of insulation as an 80 mm thick rockwool panel. As A Result PUF or PUR panels find application as wall as well as roof panels in factories and commercial buildings. It maintain the insides of a building at an optimum temperature via its insulation capacity.

Fire resisting abilities

Polyurethane is an organic substance which causes fuel the fires on a greater extent. Rockwool on the other hand is made of not natural components, which prevents fires from spreading out past a specific factor. So in a scenario where you require to have a panel that can hold the fire from spreading for a hour or two, after that rockwool is the option for you.

Sound Insulation Properties

Besides fire repellent capabilities, another huge benefit of rockwool panel is sound insulation. Rockwool fibers break down the acoustic waves and also subsides their intensity.

Setup needs some obtaining used to

Rockwool panels are heavier than polyurethane. So it requires to be taken care of with relatively even more care. Setup would certainly be easy after one has actually exercised few rounds.