Rockwool Panels

Rockwool Panels Manufacturer in India

Get Higher Insulation & Durability

with our

Rockwool Panels

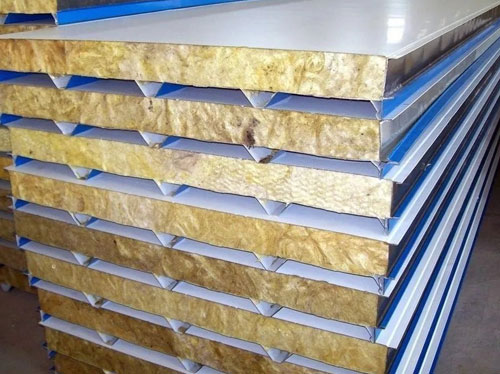

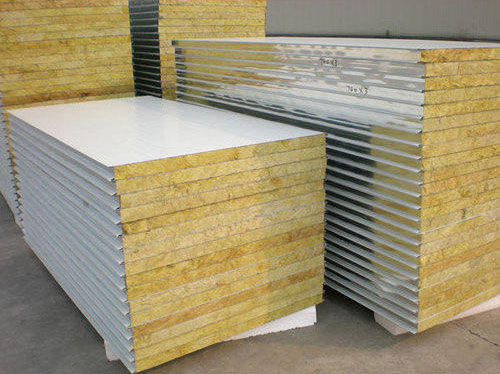

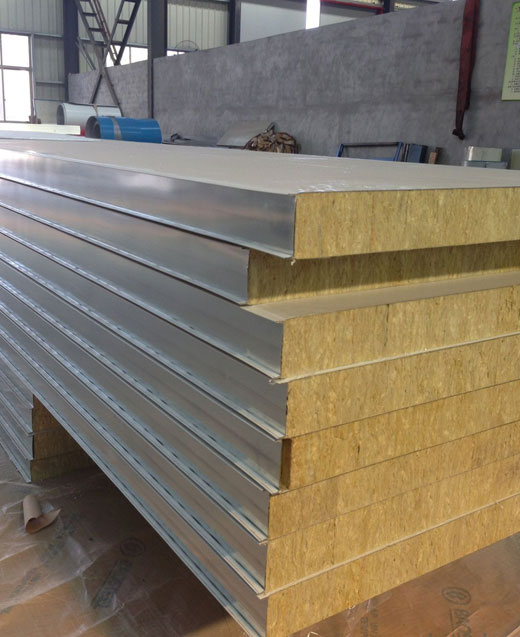

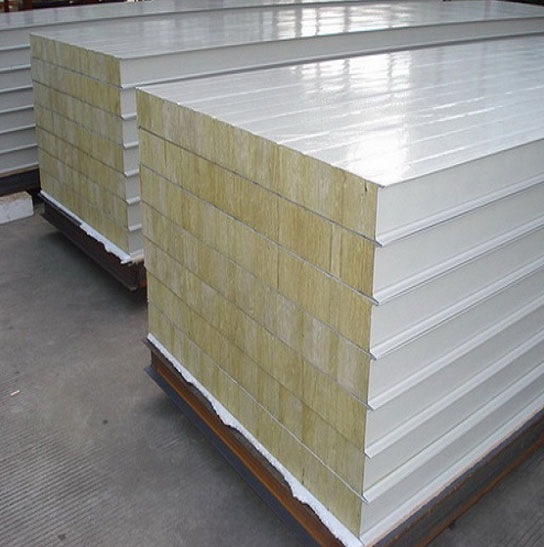

Rockwool panels are well known in the industry for fire-resistant properties. They are made from stone wool which forms the core insulation panel. This layer is sandwiched between two outer metal sheets.

The stone wool insulation material is compressed into dual-density rigid boards. The exterior surface of the insulation board is compressed more than the rest of the board. So the outer surface is stronger and offers higher compressive strength in the insulation system

EPACk Prefab

Common Types of Rockwool Panels

- Exterior wall Rockwool

Exterior wall insulation thin plastering system is a type of non-bearing insulation structure, that comprises of three layers - insulation layer, protective layer, fixed. It is fixed on the outward surface of the exterior wall. These layers carry the attributes of fire safety, insulation, waterproof capability, etc. - Single metal roof Rockwool

As the name itself sounds, this is a single layer of flexible and waterproof roofing system built with Rockwool which has thermal insulation material. It is suitable when a building is being newly constructed for roof repair. - Double metal roof Rockwool

The double-layer metal roof is a structural system where vertical locking joints at built on the top or on corrugated plates. It carries an aesthetic appeal and the inner rock wool insulation layer is filled in the center of the bottom pressed steel plate. This kind of roofing solution best meets the requirements of fire protection, sound insulation, harsh weather conditions.

EPACK Prefab

Salient Features of Rockwool Panels

- Rockwool cores have inherent non-combustible properties and acoustic capabilities.

- These panels can be assembled easily without the use of heavy machinery.

- Rockwool panels provide excellent thermal insulation.

- Rockwool offers a variety of design options for walls and roofs. Roofing can be done in multiple colors.

EPACk Prefab

Advantages of Rockwool Sandwich Panels

There are some major benefits of Rockwool panels as regards their insulation. They are listed below:

- Rockwool stone wool fibers have the capability to withstand up to 1000°C without melting. This means it can prevent the fire from spreading beyond a certain point.

- Rockwool panels have good insulation properties. For instance, when a 120mm panel is attached outward, it can reportedly take down the u-value. For occupants, this means increased comfort levels inside since temperature remains controlled.

- Rockwool stone wool also has excellent sound insulation properties.

- Rockwool is also breathable. It allows moisture to travel across the wall, which can help dissipate dampness.

- Rockwool sandwich panels are manufactured in strict accordance with the drawing layout. The construction time can be reduced by up to 40%. Therefore Rockwool sandwich panels are ideal for buildings that have to be constructed fast.

EPACK Prefab

Tips For Buying Rockwool Sandwich Panels

- Rockwool Panel Should have a density of 100 Kg/m³

- It Should be Lamela Type (Fibres of Rockwool should be standing fibres not sleeping fibres).

- Rockwool Panel should be made in a continuous sandwich panel line (should not be handmade by suppliers)

- Adhesion of the Rockwool with the Metal skin on both sides. This can be only achieved by "Two Component Gluing System in continuous line"

- Metal skin on either side of panel should have minimum 90gsm of galvanizing coating otherwise the sandwich panel tend to get trusted after some time

- The color coated metal skin on either side should have a minimum 20-25 microns of paint otherwise paint will look shabby or tear apart after some time.

- The jointing system of sandwich panel should have minimum overlap of 8-10mm otherwise it will tend to buckle after sometime