Unveiling the Versatility: A Deep Dive into Different Types of Sandwich Panels

In the ever-evolving realm of construction and insulation, sandwich panels have emerged as a revolutionary solution, seamlessly blending strength, durability, and thermal efficiency. In this comprehensive exploration, we unravel the diverse world of sandwich panels, shedding light on their types, applications, and the unparalleled advantages they offer in modern architecture and beyond.

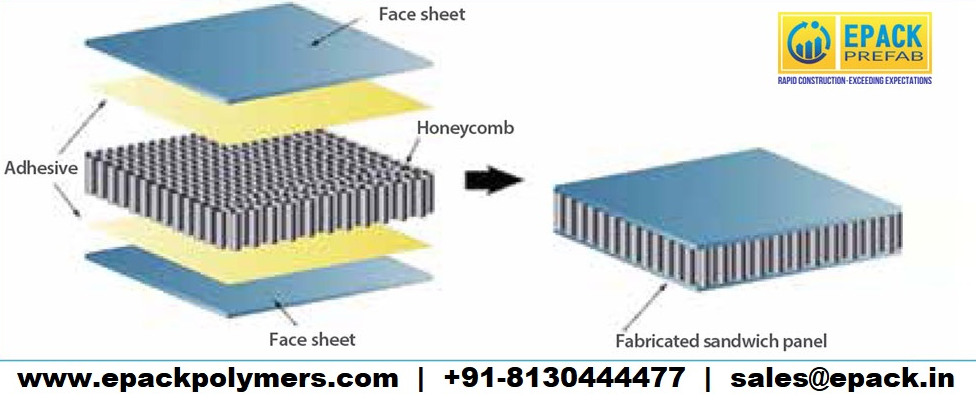

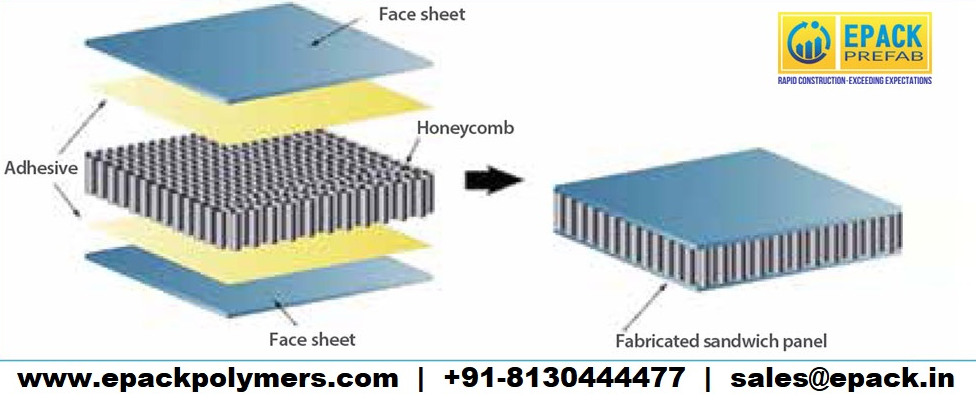

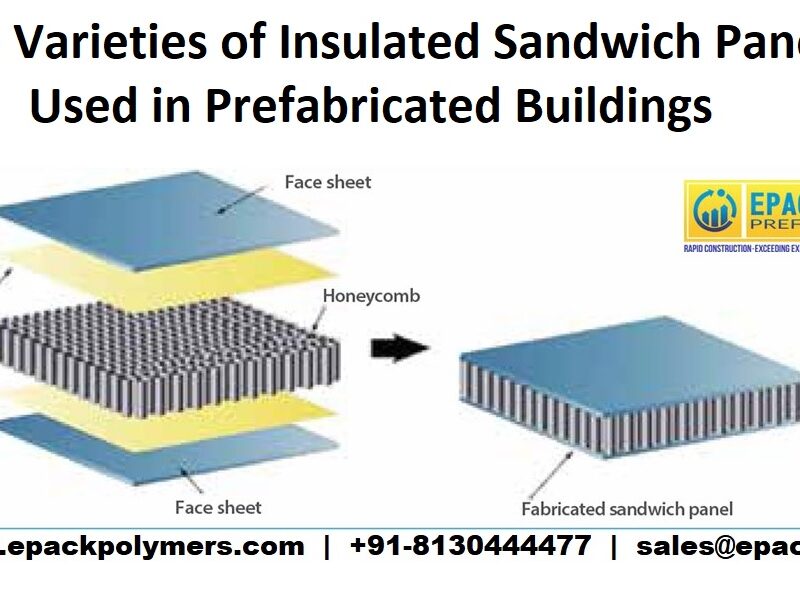

Sandwich panels, a cornerstone in contemporary construction, consist of layers that sandwich a core material, resulting in a structure that is not only robust but also lightweight. This blog post delves into the intricacies of various types of sandwich panels, providing insights into their unique compositions and applications.

Types of Sandwich Panels:

1. EPS (Expanded Polystyrene) Core Panels:

Overview: EPS core sandwich panels feature a core made of expanded polystyrene, known for its excellent insulation properties. These panels find widespread use in residential and commercial buildings, offering cost-effective thermal insulation. Applications: Ideal for roofing, wall cladding, and cold storage facilities.

2. PU (Polyurethane) Core Panels:

Overview: Sandwich panels with a polyurethane core are prized for their exceptional insulation capabilities. The polyurethane foam provides a high level of thermal resistance, making these panels an energy-efficient choice. Applications: Widely used in industries requiring temperature-controlled environments, such as warehouses and refrigeration units.

3. Mineral Wool Core Panels:

Overview: Mineral wool core sandwich panels are recognized for their fire-resistant properties. Comprising mineral fibers, these panels offer robust insulation while ensuring safety in the event of a fire. Applications: Ideal for structures where fire safety is a priority, such as industrial facilities and high-rise buildings.

4. Aluminum Honeycomb Core Panels:

Overview: Featuring an innovative honeycomb core made of aluminum, these panels strike a balance between strength and weight. Their exceptional strength-to-weight ratio makes them suitable for diverse applications. Applications: Commonly used in aerospace, marine, and architectural applications where lightweight yet strong structures are essential.

Advantages of Sandwich Panels:

- Thermal Efficiency: The insulating core in sandwich panels provides effective thermal resistance, contributing to energy-efficient buildings.

- Structural Integrity: The layered construction imparts structural strength, making sandwich panels ideal for load-bearing applications.

- Versatility: With various core materials and facings available, sandwich panels cater to a broad spectrum of applications, from residential to industrial.

- Rapid Installation: The modular nature of sandwich panels facilitates quick and efficient installation, reducing construction timelines.

A modern option for both residential and industrial building projects, sandwich panels are composite components that can be utilized to construct floorings, wall surfaces, and also roofings. Likewise referred to as shielded panels, sandwich panels contain an insulation layer, referred to as the core, ‘sandwiched’ in between 2 structural layers. Although sandwich panels have actually been commercially preferred given that the 1970s for their premium thermal efficiency, energy performance, and durability as contrasted to standard wood-framed buildings, the idea behind insulated panels really dates as far back as the 1930s.

Thanks to improvements in construction materials, sandwich panels have actually come a long way from their early prototypes. Nowadays, these panels can be crafted to endure a selection of internal as well as external problems, that makes them a prominent selection for both interior and exterior usage- implying walls along with façades, ceilings as well as roof systems. Airtight sandwich panels are likewise an outstanding selection for building cold store units, which call for details interior climate conditions to safely store anything from foods to medicine. The performance of sandwich panels varies relying on the products made use of for its core as well as its outside layers, usually referred to as the sheathing.

Nowadays, one of the most popular materials for the core are broadened polystyrene (EPS), extruded polystyrene (XPS), polyisocyanurate (PIR), polyurethane (PUR), mineral woollen (MW). Although each material features its very own benefits and negative aspects, PIR as well as PUR cores are typically much more immune to water and fire than EPS or XPS cores, and also are extra durable than mineral wool or other materials. The boards on either side of the core additionally can be found in a selection of options, the most popular being sheet metal, aluminium, OSB, plywood, fibre concrete, or magnesium oxide (MgO). Right here, also, the option of material is necessary, as OSB, plywood, and composite structural house siding panels don’t use the same degree of fire efficiency, wetness and also mould ingress resistance, as well as resilience as do sandwich panels plated with sheet metal.

Regardless of the products utilized, one of the best benefits of sandwich panels is that they are much faster to install as contrasted to ‘built-up’ systems calling for several parts. Instead of calling for walls as well as roofing to be constructed detailed– a process which is prone to hold-ups as well as errors in construction– sandwich panels are factory pre-engineered to be single-component systems, calling for very little time and energy to be constructed. This, subsequently, translates to significant cost savings in work, time as well as product costs for home builders.

Conclusion:

In the dynamic landscape of construction materials, sandwich panels stand out as a versatile and efficient solution. From EPS to aluminum honeycomb core panels, each type brings its unique set of characteristics, meeting the diverse needs of modern architecture and construction.

As we conclude this exploration into the different types of sandwich panels, it becomes evident that their adaptability and performance make them a cornerstone in contemporary building practices. Whether you’re aiming for energy efficiency, fire resistance, or structural integrity, there’s a sandwich panel type tailored to meet your specific requirements. Embrace the future of construction with sandwich panels – where innovation meets practicality.