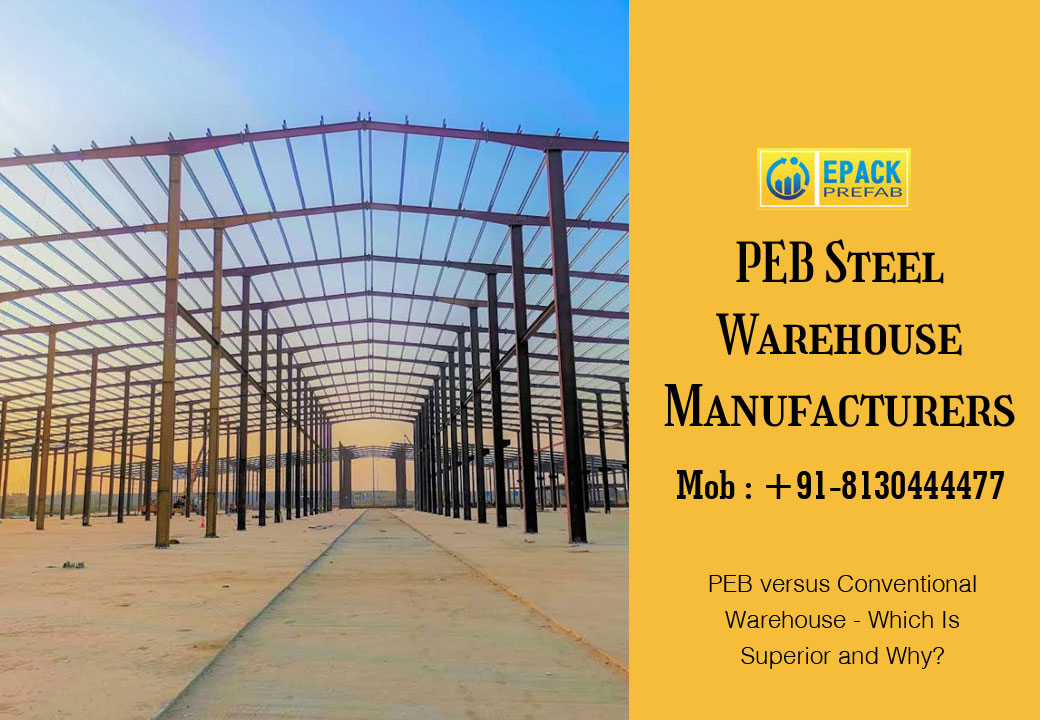

A pre engineered steel warehouse is one whose components are manufactured at a factory and then transported to the construction site for assembly and installation. The structural elements include steel beams, columns, trusses, girts, and purlins, among other components. All of the components are connected with bolts, joists, rivets, and other types of joints. The primary objective of a PEB warehouse is to provide sufficient space for storage. For this reason, steel constructions have a large span. However, what are the benefits of PEB warehouses over conventional ones?

The greatest advantage of prefabricated steel storage facility facilities is their speed of construction. Modular construction drastically reduces the duration of the construction. Steel storage sheds are also easier to relocate than traditional sheds due to their lightweight construction.

PEB Steel warehouse as opposed to conventional concrete warehouse

Stockrooms are mostly warehouses, so they are classified according to the asset distribution systems or the type of the items. To meet the growing need for storage facilities in recent years, people are increasingly turning to steel warehouses that are easy to erect. This is a strong indication that, as time passes, steel warehouses are displacing traditional ones due to their added benefits.

Building and erecting pre-engineered steel storage sheds is around 30 to 60 percent quicker. Additionally, they are easily expandable, so you may add additional storage space as needed without difficulty. Unlike concrete, this structure is fully dry and therefore more environmentally friendly.

Generally, steel-constructed warehouse or storage facilities are less expensive to develop and install than concrete-constructed storage facilities. This saves a substantial amount of production and other expenditures generally connected with creating a warehouse. PEB storage buildings are accordingly far lighter than conventional warehouses. Consequently, steel warehouses do not necessitate a structure as massive as traditional warehouses. This becomes an additional area of cost reduction.

The fewer columns and architectural elements in your building, the more space you will have in your storage facility. With steelconstruction, it is possible to build warehouses with large clearspan areas. It is possible to have a stretch of over 60 metres in a warehouse without requiring any load-bearing supports. This makes it easy to set up massive, heavy machinery and equipment according to your needs.

Common damage resulting from deterioration, mildew, termite infestations, insect infestations, and fire also favours steel warehouse over conventional ones. In addition, skillfully constructed peb storage facilities can withstand severe weather such as excessive snowfall or unrelenting rainfall and also thunderstorms. This is another significant reason for the worldwide rise in popularity of prefabricated warehouses.

EPACK Prefab is an expert in the construction of prefabricated warehouses, having spent over two decades in the industry. Our NCR-based organisation develops and manufactures products in-house, with our team handling end-to-end execution requirements.