Pre Engineered Buildings

Pre Engineered Buildings Manufacturer in India

Pre Engineered Building (PEB)

by EPACK Prefab

Pre Engineered Buildings (PEB) have emerged as a modern solution in the construction industry, offering cost-effective and durable alternatives to traditional building methods. PEBs are prefabricated structures, where various components are manufactured off-site and then assembled on-site. This innovative approach streamlines the construction process, resulting in faster project completion times and reduced overall costs.

EPACK Prefab specializes in delivering high-quality Pre Engineered Buildings tailored to the unique requirements of clients in India. With our expertise and advanced manufacturing capabilities, we offer a wide range of customization options to meet diverse project needs. From industrial warehouses to commercial complexes, our PEB solutions are designed to deliver superior performance, durability, and sustainability. Trust EPACK Prefab for your next construction project and experience the benefits of Pre Engineered Buildings.

Explore Our Range of Pre Engineered Buildings

We offer a wide range of product and service offerings to cater to your construction needs. Our expertise lies in the design, fabrication, and installation of PEB structures for various industries and applications.

Elevate your construction game with Epack Prefab's cutting-edge pre-engineered buildings!

EPACK Prefab's PEB Masterpieces: Watch Our Signature Constructions in Action

Pre Engineered Buildings: Cost-Effective and Durable Alternatives to Traditional Buildings

Pre Engineered Buildings (PEBs) offer a cost-effective and durable solution for construction projects in India. As compared to traditional buildings, PEBs are prefabricated structures designed and manufactured off-site, then assembled on-site, resulting in significant cost savings and faster construction timelines.

Pre Engineered Buildings (PEBs) offer a cost-effective and durable solution for construction projects in India. As compared to traditional buildings, PEBs are prefabricated structures designed and manufactured off-site, then assembled on-site, resulting in significant cost savings and faster construction timelines.

One of the key advantages of PEBs is their efficiency in terms of materials usage and labor requirements, leading to reduced overall project costs without compromising on quality. Additionally, PEBs are engineered to withstand various environmental conditions, ensuring long-term durability and structural integrity.

At EPACK Prefab, we specialize in delivering high-quality Pre Engineered Buildings tailored to the specific requirements of our clients in India. Our expertise in design, engineering, and manufacturing allows us to offer cost-effective solutions without compromising on quality or performance. Choose EPACK Prefab for your next construction project and experience the benefits of cost-effective and durable Pre Engineered Buildings.

Transform your vision into reality with Epack Prefab's customizable pre-engineered buildings.

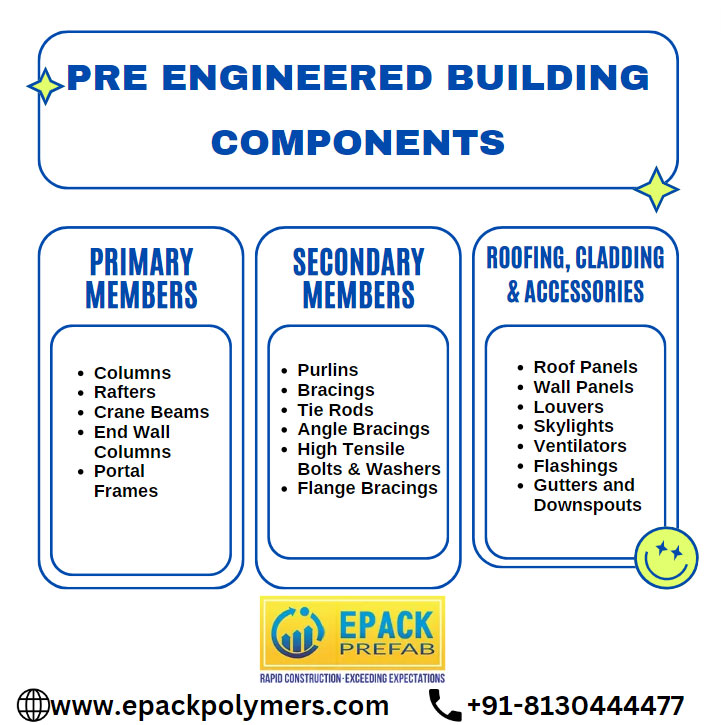

Pre Engineered Building Components

Pre Engineered Buildings (PEBs) are modern marvels of construction, offering unparalleled efficiency and versatility. These structures are composed of various components meticulously designed to deliver strength, durability, and functionality. Let’s delve into the essential components that make up a Pre Engineered Building:

- Primary Members: The backbone of any PEB, primary members include columns, rafters, and crane beams. These structural elements provide the framework and support for the entire building. Columns bear the vertical load, while rafters support the roof and crane beams facilitate the movement of heavy machinery.

- Secondary Members: Secondary members complement the primary members by providing additional support and stability. Purlins, bracings, tie rods, and angle bracings work in tandem to reinforce the structure, ensuring resilience against external forces such as wind and seismic activity. High tensile bolts and washers secure the connections between components, enhancing structural integrity.

- Roofing, Cladding & Accessories: The roofing and cladding system not only protects the building from the elements but also adds aesthetic appeal. PEBs offer a wide range of roofing and cladding options, including metal panels, insulated panels, and architectural finishes. Additionally, accessories such as gutters, downspouts, and ventilation systems enhance functionality and comfort.

Each component plays a crucial role in the overall performance and durability of the Pre Engineered Building. By leveraging advanced engineering and manufacturing techniques, EPACK Prefab ensures that every PEB meets the highest standards of quality and reliability.

With EPACK Prefab, you can trust that your Pre Engineered Building is built to last, offering unmatched strength, efficiency, and value. Experience the difference of superior craftsmanship and innovative design with EPACK Prefab’s Pre Engineered Buildings.

Contact us today to explore our range of PEB solutions tailored to your specific needs and requirements. Let us help you build a brighter future with our advanced Pre Engineered Building solutions.

Benefits of Pre Engineered Buildings

- Cost-Effectiveness: PEBs offer significant cost savings compared to traditional construction methods due to the reduced labor and construction time.

- Faster Construction: The prefabricated components of PEBs streamline the construction process, resulting in shorter project timelines.

- Design Flexibility: PEBs can be customized to meet specific design requirements, allowing for versatile architectural options.

- Durability: Engineered to withstand various environmental conditions, PEBs are known for their strength and longevity.

- Sustainability: PEBs generate less waste during construction and can incorporate eco-friendly materials, contributing to sustainability goals.

Applications of Pre Engineered Buildings

Pre Engineered Buildings are utilized across various sectors and industries due to their versatility and efficiency. Some common applications include:

Industrial Warehouses

Manufacturing Facilities

Commercial Complexes

Institutional Buildings

Aviation Hangars

Sports Arenas

Agricultural Structures

Retail Spaces

Why Choose Our Pre Engineered Buildings?

When you choose EPACK Prefab for your Pre Engineered Building needs, you benefit from:

- Expertise: Our team brings years of experience and expertise in designing and constructing PEBs to ensure the highest quality and performance.

- Customization: We offer a range of customization options to tailor your PEB to your specific requirements and preferences.

- Quality Assurance: We adhere to strict quality control measures throughout the manufacturing and construction process to deliver durable and reliable buildings.

- Timely Delivery: We prioritize timely delivery to ensure your project stays on schedule and within budget.

Our Pre Engineered Building Process

At EPACK Prefab, our Pre Engineered Building process includes:

- Consultation: We begin by understanding your project requirements and objectives through detailed consultations.

- Design and Engineering: Our team of engineers uses advanced software to design and engineer your PEB according to your specifications.

- Manufacturing: We manufacture the components of your PEB at our state-of-the-art facility using high-quality materials and precision manufacturing techniques.

- Site Preparation: Concurrently, we prepare the construction site to ensure it is ready for the installation of your PEB.

- Installation: Our experienced team installs the components of your PEB on-site, following strict safety protocols and quality standards.

- Completion: Upon completion, we conduct thorough quality checks to ensure your PEB meets our stringent standards before handing it over to you.

Customization Options for Pre Engineered Buildings

We offer a wide range of customization options to meet your specific needs and preferences:

- Building Size and Layout

- Roofing and Cladding Options

- Doors and Windows Configurations

- Interior Finishes and Accessories

- Structural Add-Ons such as Mezzanines and Canopies

These customization options ensure that your PEB is tailored to your exact requirements and specifications.

Sustainability & Pre-Engineered Buildings

Sustainability is a key focus in our Pre Engineered Building solutions. We incorporate eco-friendly materials and energy-efficient design features to minimize environmental impact and promote sustainability.

Maintenance of Pre-Engineered Buildings

Regular maintenance is essential to ensure the longevity and performance of your Pre Engineered Building. We provide maintenance guidelines and support to help you keep your PEB in optimal condition.

FAQs About Pre Engineered Buildings

What is the difference between Pre Engineered Buildings and conventional buildings?

Pre Engineered Buildings are prefabricated structures designed and manufactured off-site, while conventional buildings are constructed on-site using traditional methods.

Are Pre Engineered Buildings customizable?

Yes, Pre Engineered Buildings can be customized to meet specific design requirements and preferences.

How long does it take to construct a Pre Engineered Building?

The construction time for a Pre Engineered Building depends on various factors such as size, complexity, and site conditions. However, PEBs are generally constructed much faster than conventional buildings due to the prefabricated nature of their components.

Contact Us for Your

Pre Engineered Building Needs

For high-quality Pre Engineered Building solutions tailored to your requirements, Contact EPACK Prefab today. Our team of experts is ready to assist you in realizing your construction goals.

Overall, Pre Engineered Buildings offer a cost-effective, durable, and versatile solution for various construction needs, making them a preferred choice for projects across India. With EPACK Prefab, you can trust in our expertise, quality, and commitment to excellence.