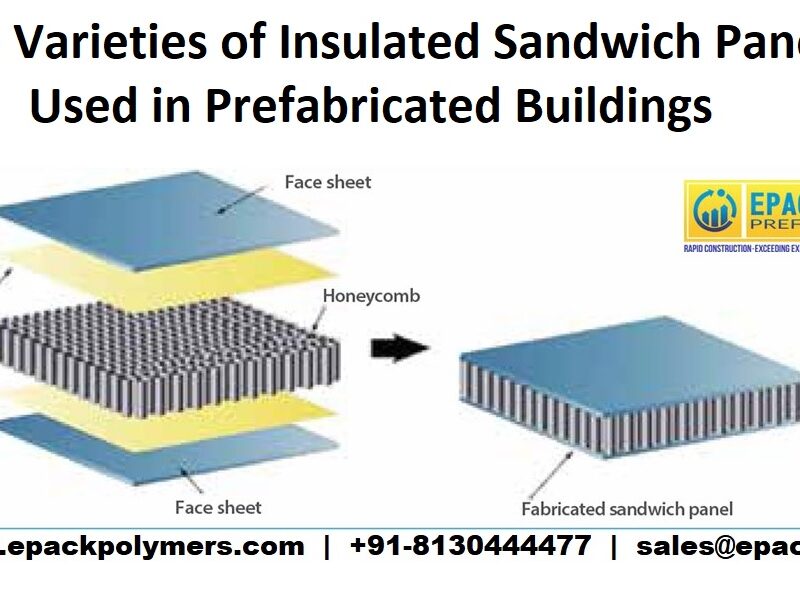

The construction industry is rapidly growing in the world over the last two decades. It is possible because of prefabricated structure construction, prefabricated construction provides various attractive features to customers which are in customer’s favor. This is the main reason behind the popularity of prefabricated structures. Sandwich panel is a prefabricated structure product that is used nowadays in almost every construction.

In the realm of modern construction, the utilization of innovative materials and technologies is pivotal to achieving efficiency, sustainability, and cost-effectiveness. Among the array of construction materials, Sandwich Panels have emerged as a game-changer, revolutionizing the building and development landscape. In this comprehensive blog, we delve into the intricacies of Sandwich Panels, exploring why they have become the preferred choice for builders and developers, with a keen focus on the offerings of EPACK Prefab.

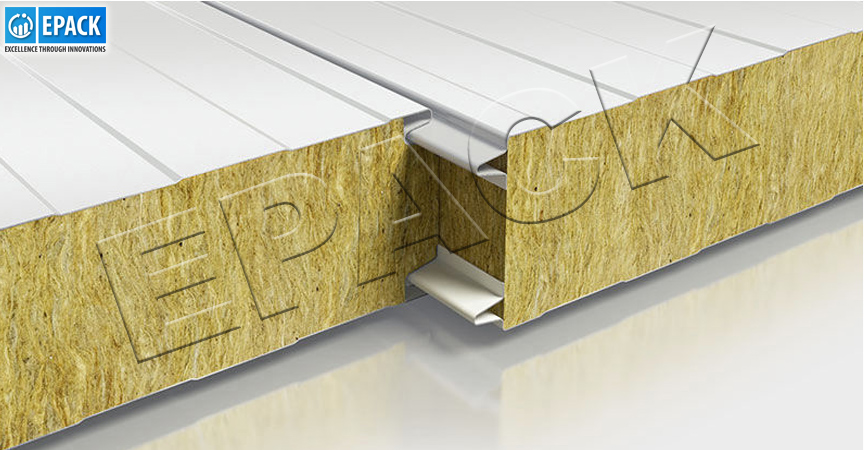

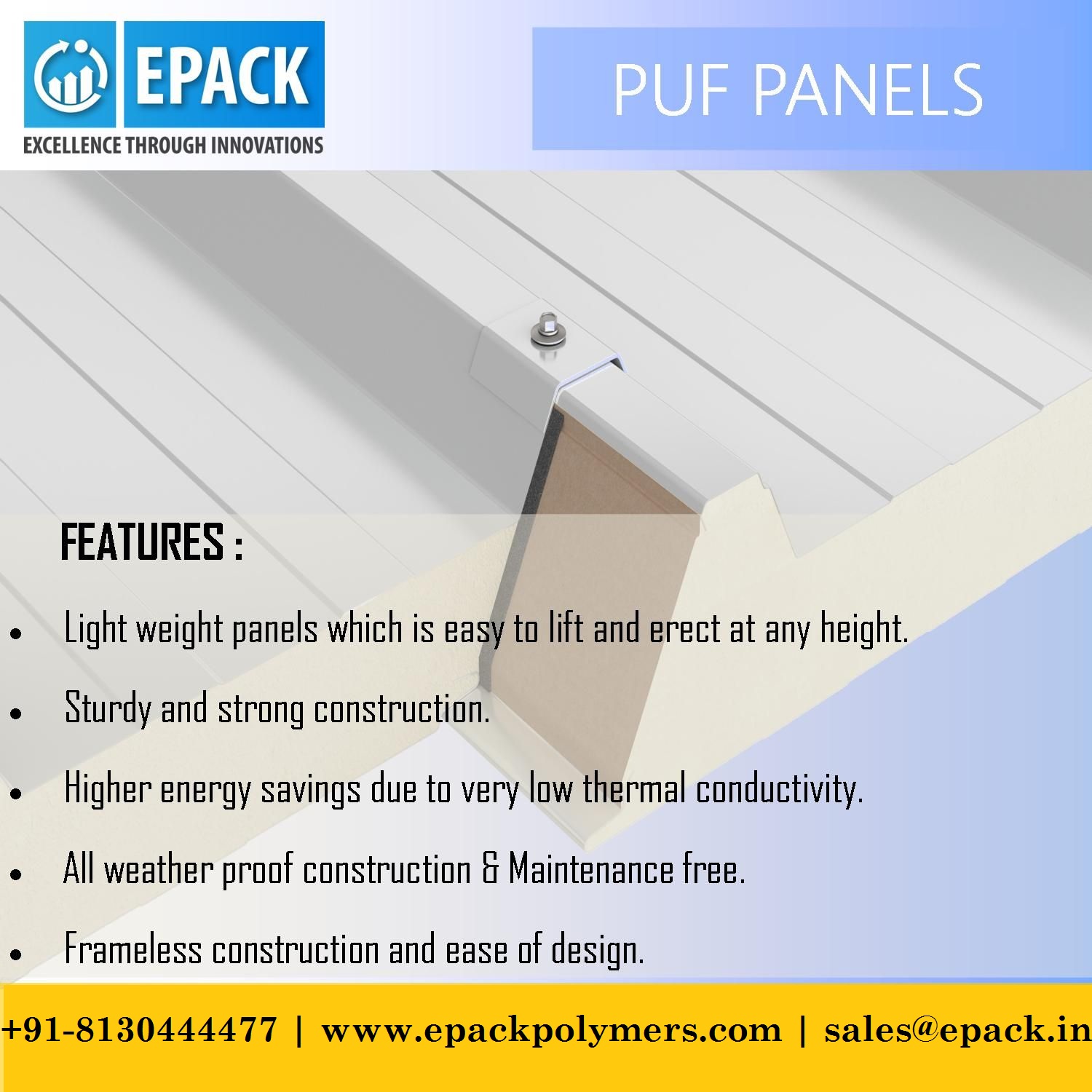

In the construction industry builders and developers actually knows the benefits of using a sandwich panel in any type of building or structure. Any kind of panel like PUF panel, EPS panel, Rockwool panel, Glass wool panel, etc. all are energy saving and save energy up to 40-50% yearly. All sandwich panels used for different purposes in the industry. EPS panel is suitable for ceiling and walls, PUF panel is used for building roofs, walls and to cater to all cooling requirements, Rockwool panel has excellent fireproof, sound-absorbing, heat-insulating, ad sound insulating properties. So Rockwool use for the control room, generator room, inverter room, etc.

Structural Advantages of Sandwich Panels

1. Exceptional Strength-to-Weight Ratio: Sandwich panels are engineered to provide remarkable strength while remaining lightweight. This unique combination makes them ideal for constructing structures that require both durability and ease of installation.

2. Thermal Insulation: The core of sandwich panels is often composed of insulating materials, contributing to superior thermal insulation. This not only enhances the comfort of the occupants but also leads to energy savings by reducing the need for extensive heating or cooling systems.

3. Sound Insulation Properties: The layered structure of sandwich panels acts as a natural sound barrier, making them an excellent choice for buildings where acoustic performance is a crucial consideration.

4. Fire Resistance: Many sandwich panels are designed to meet stringent fire safety standards, providing an added layer of protection in the event of a fire. This feature is especially crucial for buildings where safety is a top priority.

Versatility in Construction Applications

1. Speedy Construction: Sandwich panels are prefabricated, allowing for rapid and efficient construction. This not only accelerates project timelines but also minimizes on-site disruptions, making them a preferred choice for builders aiming for timely project completion.

2. Adaptability to Various Designs: The flexibility of sandwich panels makes them suitable for a wide range of architectural designs. Builders and developers can choose from different thicknesses, finishes, and colors, ensuring a seamless integration with the overall aesthetic vision of the project.

3. Cost-Effective Construction: The efficiency in construction, coupled with the reduction in labor costs and material wastage, makes sandwich panels a cost-effective choice for builders and developers. The overall affordability without compromising on quality is a significant factor driving their popularity.

Environmental Sustainability

1. Reduced Carbon Footprint: Sandwich panels often incorporate environmentally friendly materials, contributing to a reduced carbon footprint in construction. This aligns with the growing emphasis on sustainable and eco-friendly building practices.

2. Energy Efficiency: The thermal insulation properties of sandwich panels lead to increased energy efficiency in buildings. Reduced reliance on heating and cooling systems not only saves costs but also aligns with global initiatives for energy conservation.

3. Recyclability: Many sandwich panel components are recyclable, promoting a circular economy in the construction industry. This commitment to recyclability is essential for builders and developers aiming to adopt environmentally responsible practices.

The benefit of using a sandwich panel in construction areas:

Cost-Effective: These panels are cost-effective as compared with tradition construction, customer can get at affordable price. The sandwich can easily install but traditional construction is a time taking process.

Design flexibility: Prefabricated structures ranging from low-cost housing, cold rooms, clean rooms, hospitals, food storage rooms, etc. are made of using sandwich panels. If need to extend the design of any prefabricated structures then can easily be done in this construction but traditional construction does not provide this type of feature.

Cost Saving: To install the insulated panels in prefabricated structures required less labor and time, so as a result using the sandwich panel is cost-saving. Traditional construction is time taking process to complete the structure, hence require more labor & time for a long time, as a result, wastage of a lot of money in this construction.

Time & Money both are important things in today’s time. So the use of the sandwich panels in prefabricated structures is a time money-saving thing. This is the main reason why the sandwich panel is the preferred choice of builders and developers in the construction industry.